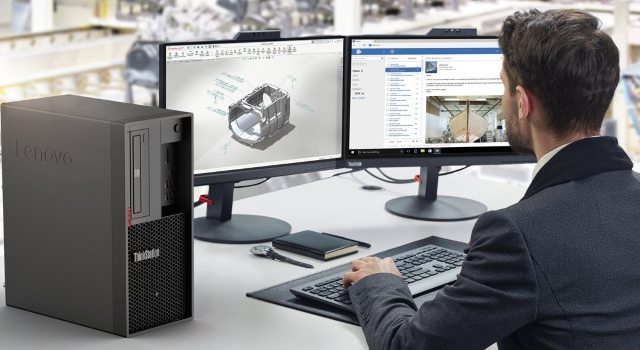

Design

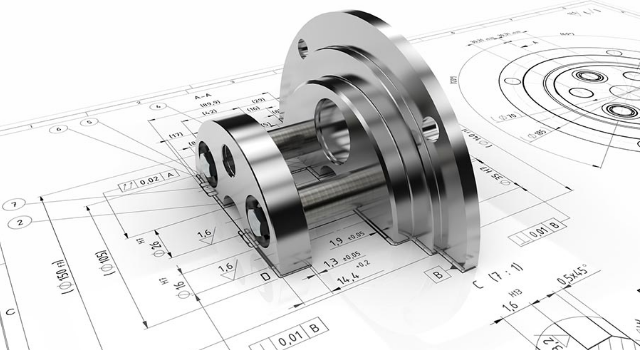

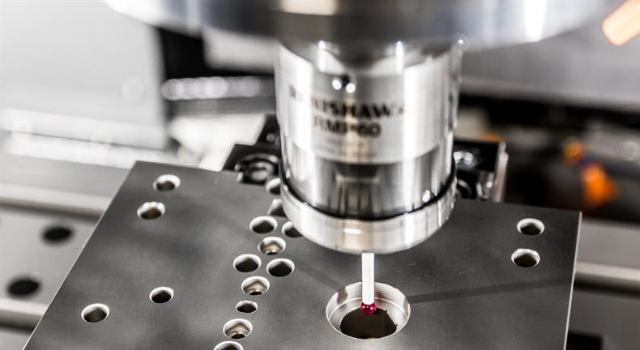

In our Design Department, tools are developed on eight state-of-the-art CAD workstations in close cooperation with the customer. We examine the feasibility of your parts and optimise the groundwork. Even in this early phase, we take subsequent economical production into account. While we may use laser technology to manufacture the first individual pieces, we already use specific pilot-series tools for fabricating prototypes. The final tools are then produced from carbide steel with the highest degree of precision. Continuous quality control and precise measurements ensure the finest end product.